TO THE HIGHLIGHT IN THE BOOKSHELF

Designing Book Covers

Enhanced with Refinement

THE FIRST 12 SECONDS!

The initial twelve seconds determine whether a book is purchased or returned to the shelf. Hence, it is of paramount importance that the book cover captures attention at first glance. Book refinement provides your book with the decisive advantage!

To ensure that your book capitalizes on these crucial first seconds, we offer a wide range of book refinement and book art. Whether you are producing an exclusive limited edition or industrially manufacturing large quantities, we identify the perfect refinement for your book.

High-quality refinement on the finished book

Stigler References

This is just a glimpse of our successfully executed projects.

Moreover, there are numerous possibilities to design your book cover and make it truly special.

Exciting insights are created through die-cutting or intricate laser cutting. enticing outer contours or an elegant embossing provide additional tangible incentives. These visual and tactile effects play a crucial role in the first few seconds.

For children's books, surprising pop-up elements or flaps for exploration are suitable; they inspire and stimulate the spirit of play.

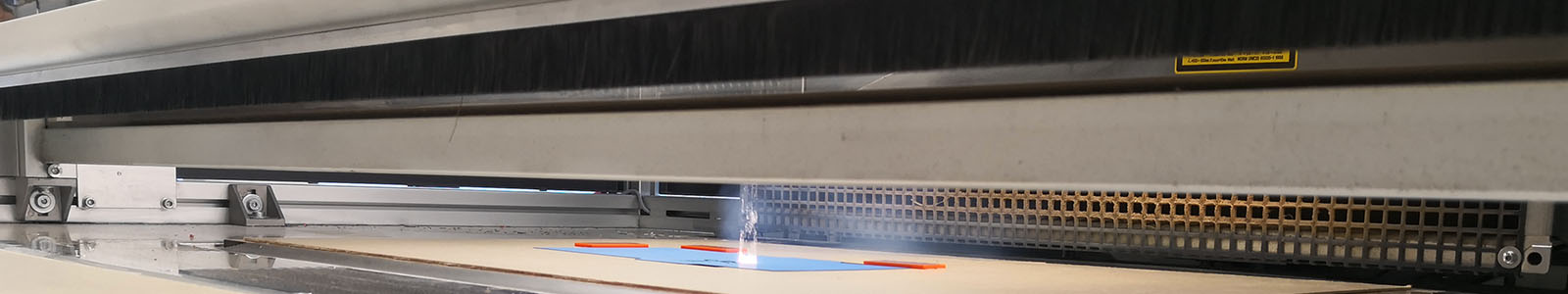

The use of state-of-the-art laser technology enables us to achieve personalized refinement of book covers or edges, book or dust jackets, wraps, slipcases, and bookmarks.

STIGLER ENHANCES - YOU BENEFIT

| Processing in the Highest Quality |

| Production in Kirchheim near Munich |

| Punctual Manufacturing |

| A Dedicated Contact for Your Project |

IDEAS FOR REFINEMENT ON THE FINISHED BOOK

- We can punch inner contours into the book cover or emboss the book cover.

- Laser-Cut on the book cover and on individual content pages.

- Laser engraving, personalized if desired, on the book cover, individual content pages, and even the book edges.

- Integrated pockets, pen loops, bookmarks, CD holders, or closure bands.

TYPES OF BOOK REFINEMENT DURING PRODUCTION

- Cellophaning of book covers with special films for visual and tactile effects and protective purposes.

- Special highlights can be achieved with hot foil embossing. Color pigments are applied to the paper using a transfer foil.

- Blind embossing creates subtle, tangible, and visible stimuli.

- Cut-outs on the printed sheets of content pages create special surprise elements. The processing of punched sheets should be coordinated in advance with the bookbinder.

BOOK COVERS & CREATING MORE DISTINCT DESIGNS

Essentially, all elements—content pages, book and dust covers, belly bands, slipcases, or bookmarks—can be refined in a coordinated manner. The possibilities are virtually limitless. To bring your visions to life, we are willing to explore unconventional paths.

Frequently askes Questions about Book-Refinement

WHAT ARE THE ADVANTAGES OF BOOK REFINEMENT?

- Refined books stand out from the crowd,

- they arouse curiosity and interest,

- convey value and appreciation, and

- provide added value through additional benefits.

HOW CAN I DESIGN A BOOK COVER?

In addition to visual design with colors and glossy effects, such as through hot foil stamping, tactile experiences play a significant role.

The diverse possibilities range from embossing to kiss-cutting and lasercut to personalized laser engraving.

With kiss-cutting or lasercut on the book cover, the view is opened to the endpaper. So, the endpaper is included as a second layer in the cover design. Through the clever combination of insight and print, even a small story can be told. The imagination and creativity are almost limitless in this regard.

WHAT SHOULD I CONSIDER IN BOOK REFINEMENT DESIGN?

Exceptional books result from the optimal collaboration of all companies involved in production and refinement. The various production steps can impact refinement, and conversely, planned refinement can influence production. Therefore, discuss your ideas and preferences with all involved parties in advance.

Here are some tips:

- Kiss-cuts or laser cuts on covers, wraps, or individual book pages can reveal normal production variations in processing (printing, folding, stitching, binding, etc.). Avoid exact alignment with the print image and the side visible through the cutout.

- It's better to creatively integrate "overfills" here.

- Do not print outlines or cut contours.

- The material of the book cover can play a significant role in laser cutting. With gray and black boards, the cut edge tends to be sooty. These boards should only be used when very small elements are cut out that cannot be touched.

- Light boards are generally suitable for laser-cut books.

- Avoid sharp contours and narrow bridges in cutout motifs. The boards can split at these points during cutting.

DOES THE BOOK THICKNESS MATTER?

Kiss-cuts or laser refinement on the finished book can be done regardless of the book's thickness. However, the size and contour of the cutout and the distance from the spine may be significant. We are happy to advise you in the planning phase.

Mailing Book Refinement Topic: Board and Processing

The Idea

Refining books is an exciting task. Optimal results can be achieved when all components are finely tuned. The choice of board plays a crucial role in this process. We consistently witness the transformation of books into stunning works when the board is selected to complement the desired processing. Unfortunately, we also observe the impact of using the wrong board on the final outcome. Hence, the idea emerged to encapsulate the essential strengths and weaknesses in a mailing.

Development and Testing Phase

Our primary objective was to elucidate the processing capabilities of various paperboards. Ultimately, we chose to produce cards from different paperboards with various treatments. In this way, we aim to demonstrate how the paperboards react to kiss-cutting and laser processing, providing you with essential foundational information and visual aids for conceptualizing your book projects.

As we were concurrently engaged in a project related to Ginkgo, the foundational design was swiftly determined. Opting for a production without a printed image was a deliberate choice to ensure unadulterated results. It was crucial for the outcomes to distinctly showcase what is achievable and how the paperboards respond.

Following the selection of colors and coordination of design elements, we commenced the production tests. The design was adjusted in certain areas based on the test results. Even with optimal material selection, there are instances where laser contours may need slight modifications.

Are you interested in our sample set or would you like to be added to our mailing list? Simply send us a brief message.

Sometimes, the choice of cardboard makes the difference.

Small Data Adjustment with Significant Impact

The photos clearly illustrate how minor changes to the data can enhance the laser result.

The small image shows the laser engraving with the original data. The spacing was slightly too narrow, and the ends were too sharp; the fumes could not be adequately extracted and settled on the product.

In the large photo, the result after data optimization is visible.

The overall impression has not changed significantly, but the quality has been significantly improved.

Lightweight Boards are Particularly Suitable for Laser-Cutting

Laser-cutting allows for significantly more intricate contours compared to traditional die-cutting. In the case of light boards, the cut edges may change color, but they do not become rusty and do not transfer color.

Simpler shapes can also be effectively realized through die-cutting, with the material color remaining unchanged along the cutting edge.

In the photos, you can observe wooden board and whiteboard each with a laser-cut edge and a die-cut edge.

Processing Tests for Exceptional Results

With the planned original material and the desired processing, we are pleased to conduct tests for you. This allows us to determine the optimal components before the start of book production.

The design is often crucial in choosing bookboard. If complex contours need to be implemented, this can only be achieved with laser cutting. In this case, light boards should be used. Simpler shapes, such as circles or rectangles, can generally be kiss-cut. Here, gray or black boards can be used.

Book Refinement – Is that all?

Of course not! In addition to book refinement, we specialize in laser finishing, die-cutting, embossing, kiss-cutting, and folding cardboard.

Discover more about our expertise and the extensive range of services we offer.

To our Services