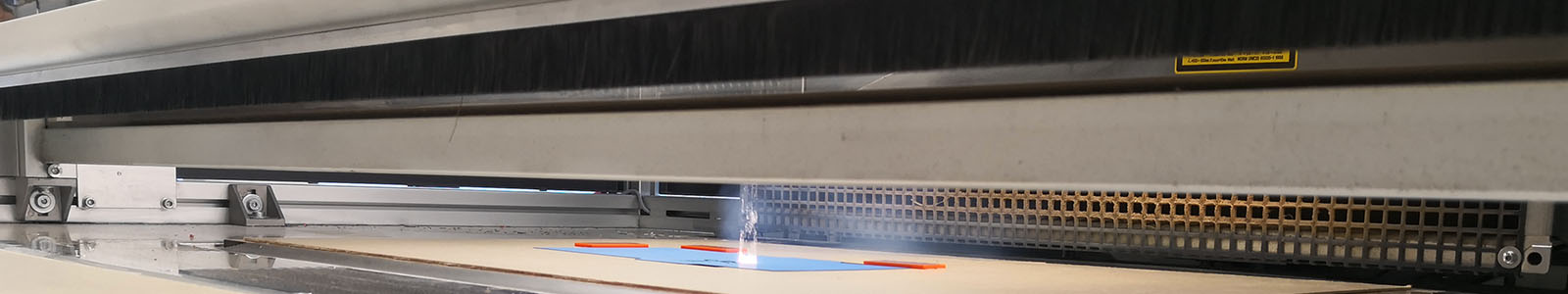

Kiss-cut - the process for specialized applications.

Ideal for the production of labels in freeform and complex packaging.

Kiss-cutting involves a delicate touch in the machine setup. The depth of the kiss-cutting blades must be finely calibrated to a fraction of a millimeter. The sticker needs to be perfectly cut, ensuring that only the top layer is cut without damaging the backing sheet. This precision is crucial for easy peeling of self-adhesive labels. In the case of packaging, the material must be scored at the precise depth, facilitating neat folding of the paper while maintaining structural integrity.

| You will receive thorough consultation. |

| Our team is well-trained and motivated. |

| We produce with a focus on quality and ensure timely delivery. |

| A versatile machine park is at your disposal. |

When it comes to stickers, one often thinks of adhesive images for children or for promotional purposes, perhaps even product labels or warning signs. However, kiss-cut adhesive films are also used in production and technology, for example, as self-adhesive stencils or covers. You can also have keyboard films and front and function films kiss-cut with us.

The kiss-cut forms are created individually and on a per-order basis for you. We achieve the best possible quality by perfectly aligning the components used with your product. In a kiss-cut form, both scoring lines and cutting and kiss-cutting knives can be installed. This allows for scoring, cutting, and kiss-cutting/creasing in a single operation.

We are happy to store the kiss-cut forms professionally for you after production, so they are readily available for the next use.

For kiss-cutting, PDF data or data from common graphic programs serve as templates. Since these are used for the construction of the kiss-cut form, the kiss-cutting shop only needs the contours. The different cutting lines can be in different colors from other lines. Alternatively, fold or perforation lines can be represented as dotted or dashed. If different processes are combined, no additional files are needed. Precision is required in the production of the kiss-cut form for notch-free kiss-cutting, and we coordinate with the kiss-cut form builder.